Shijiazhuang, Hebei, China

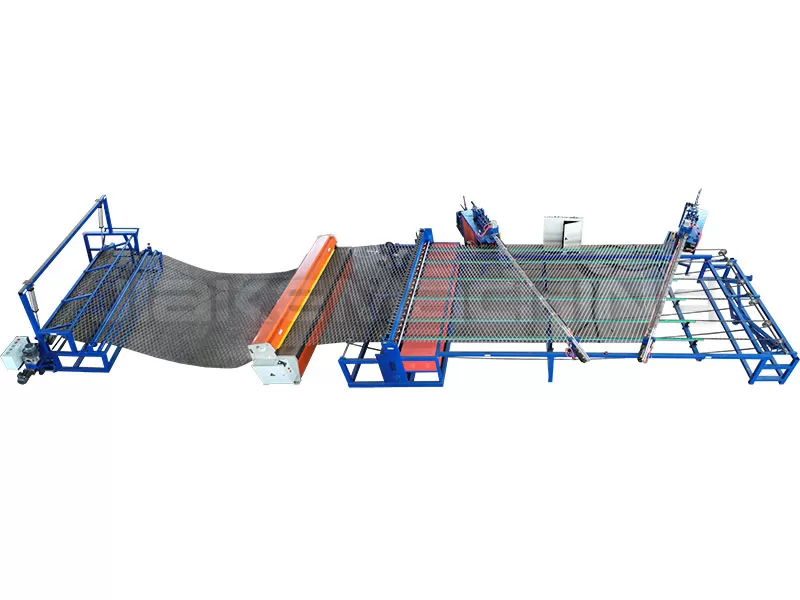

Main categories: Mesh Welding Machine/Welded Mesh Machine/Reinforcing Mesh Welding Machine/Chicken Cage Welding Machine/Wire Mesh Machine

Electric Annealing Furnace

machine video

PRODUCT DESCRIPTION

The well type resistance furnace is composed of furnace body, furnace lining, heating element, stainless steel liner, furnace cover, control system and other accessories.

1. Furnace body

The shell of the electric furnace is made of 3mm steel plate, and the bottom of the furnace is welded with a channel steel frame structure. Furnace body structure is integral, firm structure.

2. Furnace lining

The furnace lining of this electric furnace adopts a structure combining refractory bricks and refractory fiber cotton, that is, the furnace bottom is built with refractory bricks, and the furnace body is made of refractory fiber structure.

Furnace bottom: built with refractory bricks, the lower layer of the furnace bottom is paved with lightweight insulation bricks, and the upper layer is paved with three-grade high-alumina bricks, which is convenient for the load bearing of workpieces.

Furnace body: It adopts full refractory fiber structure,and the thickness of refractory fiber is 330mm, which has excellent energy-saving performance. Compared with brick resistance furnace of the same

specification, it can save energy by about 35%, and double the heating speed. The service life is much longer than that of brick furnaces.

3. Heating element

The heating element of the electric furnace adopts 0Cr21Al6Nb high temperature resistant resistance band, which is installed on the side wall and bottom of the electric furnace, and the resistance band is fixed with special high alumina ceramic nails, which is firm and reliable. This hanging side structure has high radiation efficiency, which strengthens the heat exchange in the furnace and improves the thermal efficiency of the furnace. The heating elements of the electric furnace are all made of resistance bands, with small surface load and long service life.

4. Furnace cover

The furnace cover is composed of a steel structure shell and a full-fiber lining. The thermal condition of the overall frame ensures no deformation and is durable. Guarantee its long service life. The furnace cover is hoisted, which is easy to operate and maintain.

5. Stainless steel liner

The stainless steel liner is made of 304 stainless steel, the head and the bottom cover, the wall thickness is 10mm, the cover thickness is 8mm.

6. Temperature control system

The electric furnace is controlled in 3 zones. It is controlled by a 7-inch color touch screen smart meter and a solid-state relay. The temperature control accuracy is high, the furnace temperature is stable, and the temperature difference fluctuation is small, ensuring the safe and reliable normal use of the electric furnace. The smart meter on the touch screen can be started with one key, including the process curve storage function, and the temperature recording function of each zone. The operation is more concise.

Technical parameter

| Model |

RJ3-240-9 ( single pot or double pots ) |

| effective size |

1350×2650 (mm)-customized |

| Dimensions |

2200×3100(mm)-customized |

| Loading wire space |

1000mm×2400mm (height)-customized |

| Rate power |

240kw |

| Number of heating zones | 3 districts (upper, middle, lower) |

| Rated voltage | 380V, 50 HZ or as per client’s need |

| Max. working temperature | 1000℃ |

| Working temperature | 950℃ |

| Electric control system | PID Intelligent control |

| Temperature precision | ±2.5℃ |

| Temperature distribution | ±15℃ |

| Furnace floor | Without bottom heating |

| Theoretical load | 5T-customized |

| Lifting mechanism |

Hoisting furnace cover |

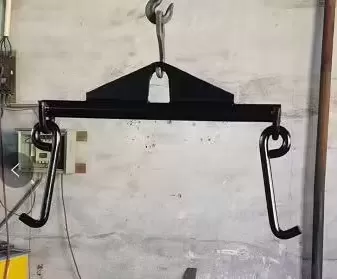

Hoisting hook

It helps to hoist the stainless steel liner.

Pressing device

to press the wires then to load more wires

COMPANY PROFILE

EXHIBITION AND EXCHANGE

ENTERPRISE CERTIFICATE

WHY CHOOSE US

about us

Hebei Jiake Welding Equipment Co., Ltd., founded in 2007, is located at the junction of Beijing, Tianjin, and Shijiazhuang—Anping County, which is famously known as the “Hometown of Wire Mesh” in China. The company has experienced steady and rapid development, now employing over 100 people. Jiake also has its own wire mesh machinery and several pilot plants, supported by a strong technical team and advanced production and inspection equipment.

FAQ

Q: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.

Q: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our technology to develop the department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience with exporting. And we can supply the CE certificate, Form E, passport, SGS report, etc, your customs clearance will be no problem.