Shijiazhuang, Hebei, China

Main categories: Mesh Welding Machine/Welded Mesh Machine/Reinforcing Mesh Welding Machine/Chicken Cage Welding Machine/Wire Mesh Machine

3-6mm roll mesh welding machine

machine video

Product Description

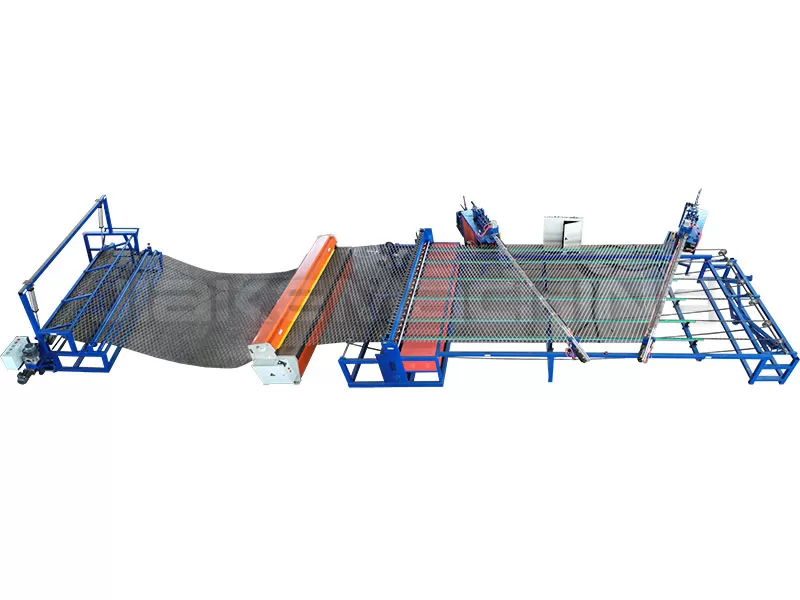

1. This machine can make both panel mesh and roll mesh.

2. Line wires are fed from wire coils automatically and through straightening rollers. Crosswire should be pre-cut and fed by a crosswire hopper automatically.

3. Servo motor&planetary reducer for pulling mesh, more precise.

4. Equipped with cutting machine to make panel mesh and rolling machine to make the rolled mesh.

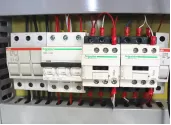

Main electrical components

(Japan) PLC

(Taiwan) touch screen

(France) low-voltage apparatus

(Switzerland Sweden) switch

(France) air switch

(Japan) power supply

(Taiwan) inverter

(South Korea) encoder

(Japan) servo drive

Main motor & planetary reducer

connect the main axis directly, big transmission torque, suitable for high welding speed.

High stability.

Welding Electrodes

Upper-20mm diameter.

Lower-20*20*20mm can be used 6 sides.

The welding electrode distance can be adjusted.

Cast water-cooling welding transformers

Water-cooling system for welding transformer and lower electrodes, to decrease the high welding temperature, efficiently and obviously, transformers’ and electrodes’ life is extended much. Especially popular in tropical areas like India, UAE, or summer time.

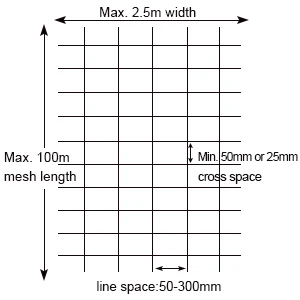

Technical

AUXILIARY EOUIPMENT

1.Mesh-cutting-machine

2.butt welder

3.Water-cooling-device

4.Air-compressor,-drier,-and-air-tank

COMPANY PROFILE

EXHIBITION AND EXCHANGE

ENTERPRISE CERTIFICATE

WHY CHOOSE US

about us

Hebei Jiake Welding Equipment Co., Ltd., founded in 2007, is located at the junction of Beijing, Tianjin, and Shijiazhuang—Anping County, which is famously known as the “Hometown of Wire Mesh” in China. The company has experienced steady and rapid development, now employing over 100 people. Jiake also has its own wire mesh machinery and several pilot plants, supported by a strong technical team and advanced production and inspection equipment.

FAQ

Q: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.

Q: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our technology to develop the department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience with exporting. And we can supply the CE certificate, Form E, passport, SGS report, etc, your customs clearance will be no problem.