Shijiazhuang, Hebei, China

Main categories: Mesh Welding Machine/Welded Mesh Machine/Reinforcing Mesh Welding Machine/Chicken Cage Welding Machine/Wire Mesh Machine

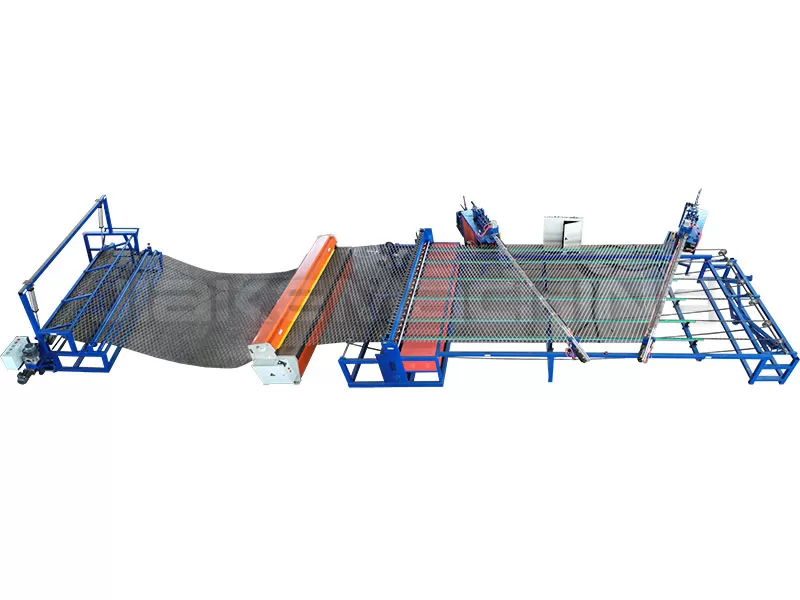

Chain link fence machine

machine video

PRODUCT DETAILS

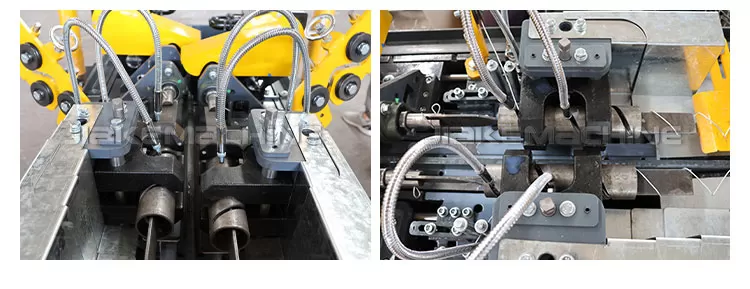

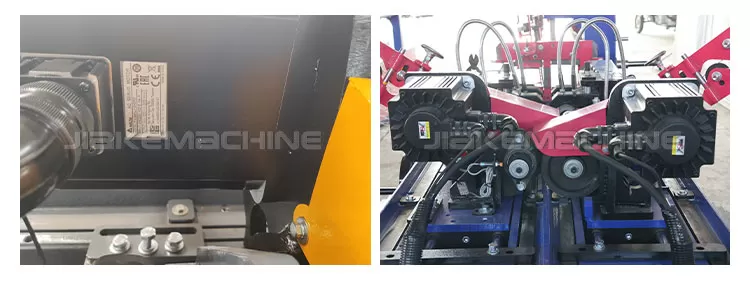

A. Double motor double die wire feeding method

B. Two servo motors and synchrony belt, more precise and easy to weave hard wire.

C. Machine electronic components equip world famous brands, very easy to operate, making the service life of the machine longer.

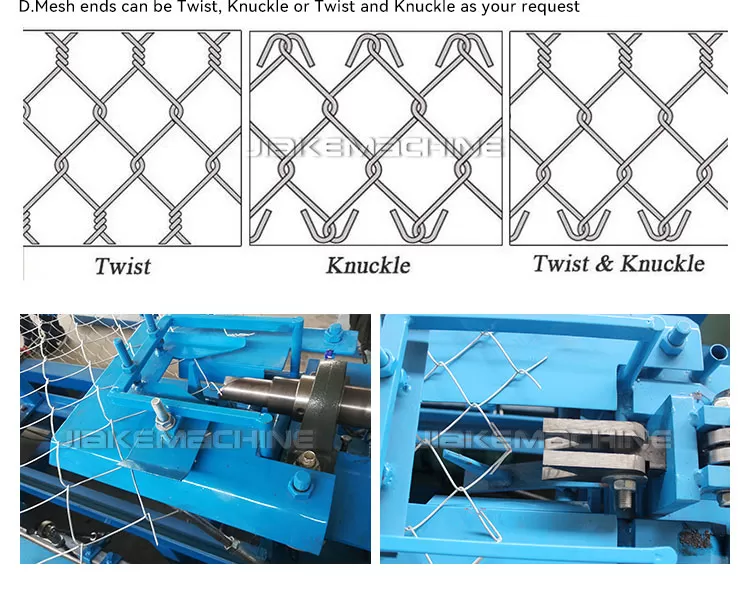

D. Mesh ends can be Twist, Knuckle or Twist and Knuckle as your request.

E. Automatic roll netting device

The machines are equipped with a rolling net device, which can reduce costs, of course, it can be selected according to your needs.

AUXILIARY EQUIPMENT

Technical Parameters

| odel | DP20-100DD, Double motor Double wires |

| Capacity | opening 40mm 80-100 square meters/h

opening 50mm 120-160 square meters/h opening 60mm 150-180 square meters/h opening 75mm 180-200 square meters/h opening 100mm 200-260 square meters/h |

| Wire diameter | 1.5-4.5mm, wire work with reasonable opening |

| Mesh opening | 25-100mm, opening work with reasonable wire |

| Weaving width | 2M, 3M, 4M, 6M

Width as per your request |

| Max length of mesh | 30m, adjustable freely as your request. |

| Raw material |

Galvanized wire, PVC Coated wire, etc. |

finish product

RELATED PRODUCTS

| Model | DP25-80, double wire feeding. | DP20-100,single wire feeding |

| Capacity speed |

120 to 180 square meters/hour, 290-430kgs/hour if 3mm wire and 50*50mm hole size. |

70-80 square meter per hour |

| Wire diameter |

1.8-4mm |

1.3-4mm |

| Mesh opening |

25-100mm |

20-100mm |

| Weaving width |

Max. 3m |

Max. 3 m |

| Weaving length |

30m, adjustable freely as your request. |

30m, adjustable freely as your request. |

| Raw material |

Low carbon wire like Galvanized wire, PVC Coated wire. |

Low carbon wire like Galvanized wire, PVC Coated wire. |

COMPANY PROFILE

EXHIBITION AND EXCHANGE

ENTERPRISE CERTIFICATE

WHY CHOOSE US

about us

Hebei Jiake Welding Equipment Co., Ltd., founded in 2007, is located at the junction of Beijing, Tianjin, and Shijiazhuang—Anping County, which is famously known as the “Hometown of Wire Mesh” in China. The company has experienced steady and rapid development, now employing over 100 people. Jiake also has its own wire mesh machinery and several pilot plants, supported by a strong technical team and advanced production and inspection equipment.

FAQ

Q: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.

Q: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our technology to develop the department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience with exporting. And we can supply the CE certificate, Form E, passport, SGS report, etc, your customs clearance will be no problem.