Shijiazhuang, Hebei, China

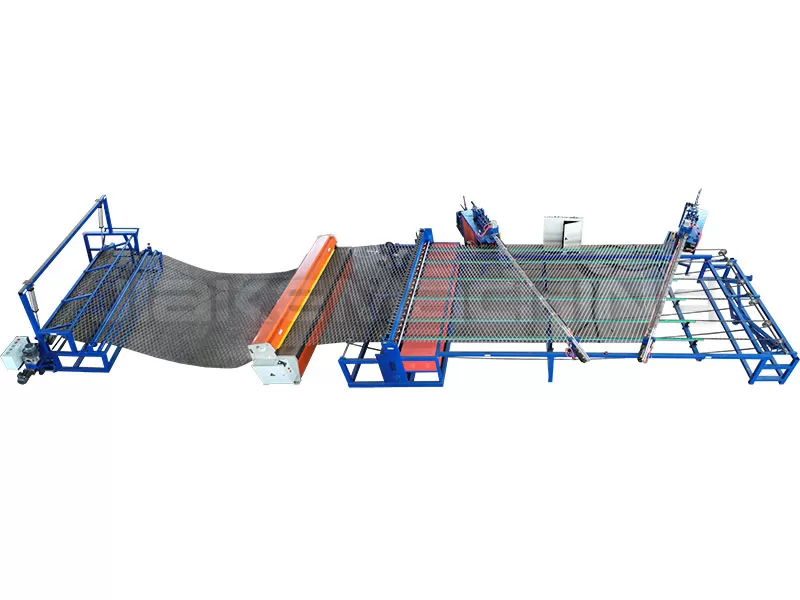

Main categories: Mesh Welding Machine/Welded Mesh Machine/Reinforcing Mesh Welding Machine/Chicken Cage Welding Machine/Wire Mesh Machine

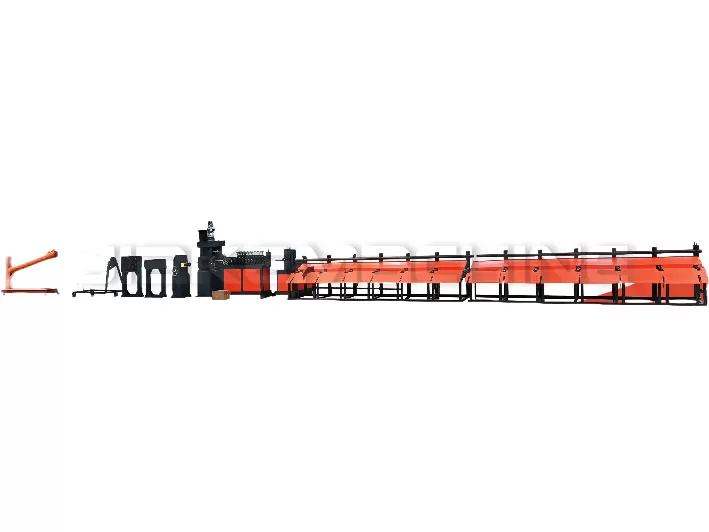

Cold rolling steel bar ribbed machine

machine video

Product Description

Raw material is hot-rolled low carbon steel round bar.

Usage: This production line is mainly to make 4-12mm reinforcing steel bars with three-side crescent shape ribs. Finished product is widely used in highway, road, city planning and construction.

Gearbox Reducer, large torque, low noise, durable.

Advanced frequency inverter technology, can save electricity.

The rolling wheel part are designed with water cooling system, suitable for high speed.

Process:

Raw material–Wire guide bracket–Mechanical descaler–Lubrication part–Drawing machine for reducing and ribbing–straightening&cutting/coiling

TECHNICAL PARAMETERS

| Type: LZ-20000T |

| Motor capacity: 75kw (reducing+ribbing)+15kw(straightening)+11kw (servo flying cutting); 11kw (coiling) |

| Straightening accuracy: ±2mm; Cutting accuracy: ±5mm |

| Reduced diameter: less than 2mm, more than 0.5mm

To make 12mm rebar, you can use max.13mm material; To make 10mm rebar, you can use max.12mm material, To make 8mm rebar, you can use max.10mm material. |

| Mode of adjustment: speed Inverter |

| Rolling speed: with wire coiling machine, max.150m/min

with wire straightening and cutting machine GTY5-12, 5-12m cutting length with max.150m/min. 4m cutting length with max.120m/min. 3m cutting length with max.90m/min. |

| Total weight: 6.2T |

AUXILIARY EOUIPMENT

FINISHED PRODUCT

COMPANY PROFILE

EXHIBITION AND EXCHANGE

ENTERPRISE CERTIFICATE

WHY CHOOSE US

about us

Hebei Jiake Welding Equipment Co., Ltd., founded in 2007, is located at the junction of Beijing, Tianjin, and Shijiazhuang—Anping County, which is famously known as the “Hometown of Wire Mesh” in China. The company has experienced steady and rapid development, now employing over 100 people. Jiake also has its own wire mesh machinery and several pilot plants, supported by a strong technical team and advanced production and inspection equipment.

FAQ

Q: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.

Q: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our technology to develop the department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience with exporting. And we can supply the CE certificate, Form E, passport, SGS report, etc, your customs clearance will be no problem.