Shijiazhuang, Hebei, China

Main categories: Mesh Welding Machine/Welded Mesh Machine/Reinforcing Mesh Welding Machine/Chicken Cage Welding Machine/Wire Mesh Machine

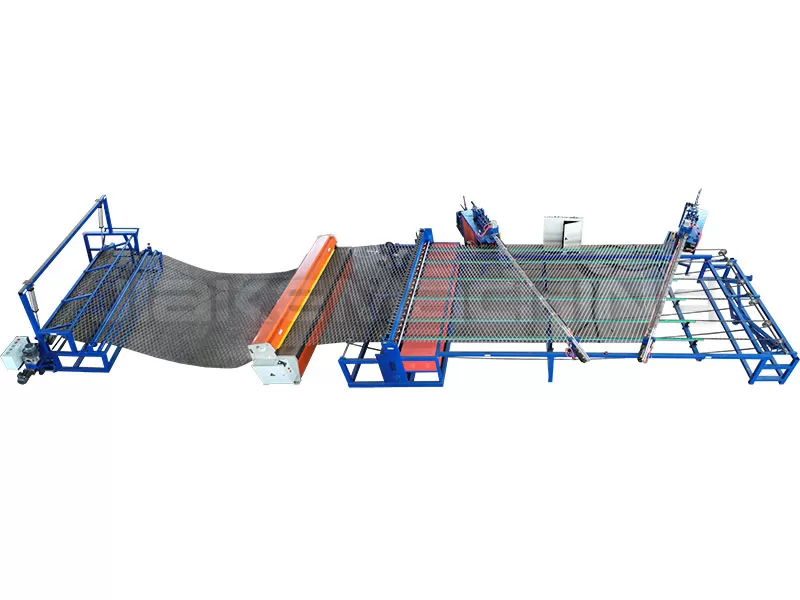

Razor barbed wire machine

machine video

machine photos

How Does Razor Barbed Wire Machine Work

Razor barbed wire machine mainly consists of punching machine and coiling machine.

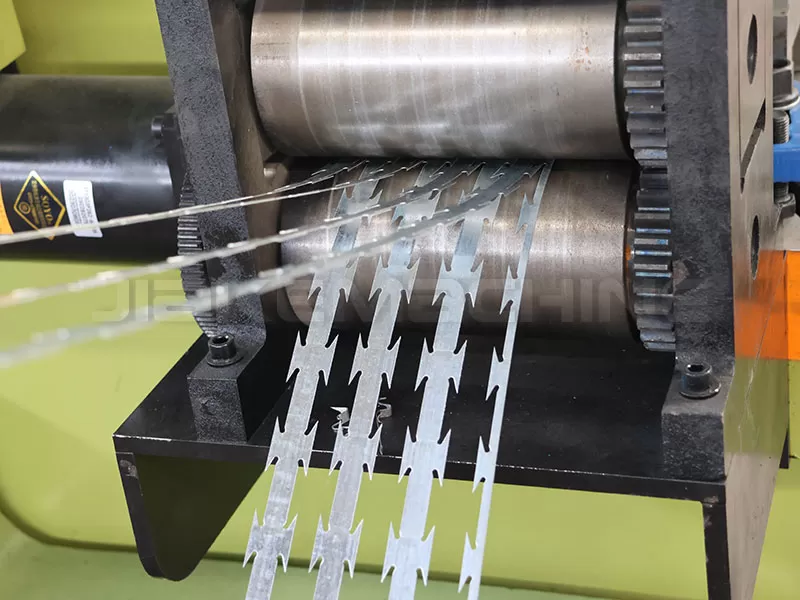

Punching Machine:

The punching machine is responsible for cutting steel tapes into different razor shapes using various molds.

It utilizes molds to create razor blades on steel strips, giving them the characteristic sharp and pointed edges.

This process ensures uniformity in razor shapes and dimensions according to the specific requirements.

Coiling Machine:

Once the steel tapes are punched into razor shapes, the coiling machine takes over.

Its primary function is to wrap the razor strip onto a steel wire core.

The coiling machine then winds up the finished razor barbed wire into rolls of various lengths, ready for deployment.

Machine Advantages

| 1 | Automatically complete production line, operator friendly and higher speed. |

| 2 | Automatic decoiler holding max. 2tons steel sheet; its motor made of copper leads. |

| 3 | Punch machine adopts step motor to feed steel sheet fast and smooth |

| 4 | Punching machine adopts high quality bush, not easy to burn down |

| 5 | Punch machine adopts button switches and foot switch, easy to operate. |

| 6 | Razor coiling machine adopts inverter to adjust working speed, more precise, long life. |

| 7 | Customized mold saving 20% raw materials; hot-cast mold, one year life. |

| 8 | Slitting frame and recoiler to wind up razor tapes rolls tightly. |

| 9 |

Chines famous brand motor in coiling machine for smooth speed adjustable. |

Technical Parameters

| Model | 25T | 40T | 63T | Coiling machine |

| Power | 2.2 kW | 4 kW | 5.5 kW | 1.5 kW |

| Producing speed | 70 times/min | 75 times/min | 120 times/min | 3-4 ton/8h |

| Pressure | 25 Ton | 40 Ton | 63 Ton | — |

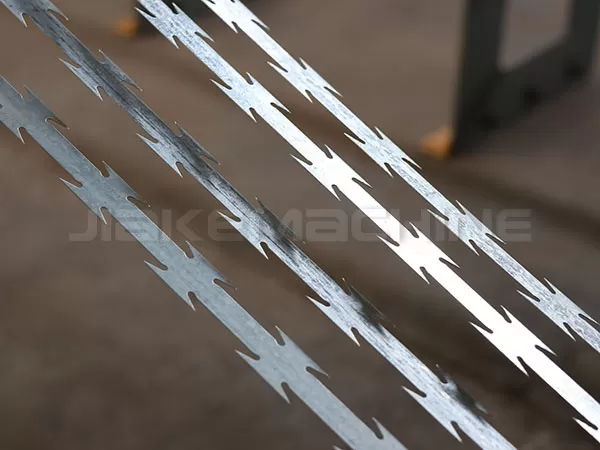

| Material thickness and wire diameter | 0.5±0.05 mm, according to your requirement | |||

| Material of sheet | GI and stainless steel | GI wires | ||

| Voltage | 3 phase 380V/220V/440V/415V, 50HZ or 60HZ | |||

| Weight | 2200 kgs | 3300 kgs | 4500 kgs | 300 kgs |

finish product

COMPANY PROFILE

EXHIBITION AND EXCHANGE

ENTERPRISE CERTIFICATE

WHY CHOOSE US

about us

Hebei Jiake Welding Equipment Co., Ltd., founded in 2007, is located at the junction of Beijing, Tianjin, and Shijiazhuang—Anping County, which is famously known as the “Hometown of Wire Mesh” in China. The company has experienced steady and rapid development, now employing over 100 people. Jiake also has its own wire mesh machinery and several pilot plants, supported by a strong technical team and advanced production and inspection equipment.

FAQ

Q: Where is your factory located?

A: Our factory is located in Anping county, Hebei Province of China. The nearest airport is Beijing airport or Shijiazhuang airport. We can pick you up from Shijiazhuang city.

Q: How many years are your company engaged in the wire mesh machines?

A: More than 25 years. We have our technology to develop the department and testing department.

Q: Can your company send your engineers to my country for machine installation, worker training?

A: Yes, our engineers went to more than 100 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A: We have much experience with exporting. And we can supply the CE certificate, Form E, passport, SGS report, etc, your customs clearance will be no problem.